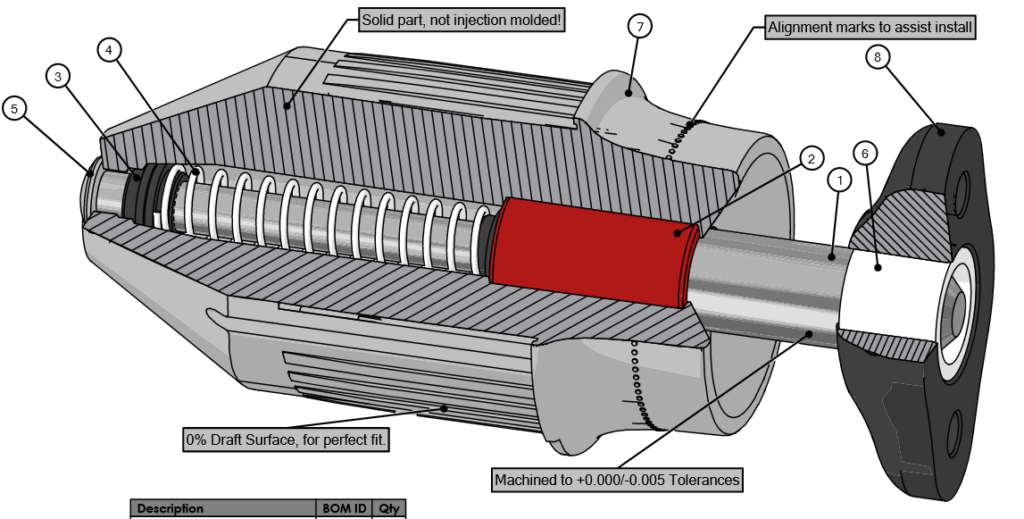

Check this thing out! Why “5B”? Because it takes 5 separate bushings and bearings to ensure that every moving object is in contact with a tolerance controlled surface and to eliminate EVERY metal on metal interaction. With a 3/4″ spindle just might be the coolest part of our screen system.

- Exterior casing is NOT injection-molded, which allows us to maintain perfectly collinear surfaces with our roller tube, which eliminates any wiggle or rocking in the assembly.

- Custom machined parts to +0.000/-0.005 tolerances. Our machinist bragged that this solid stainless steel part will likely outlast the building it’s installed on.

- Alignment marks included on casing, which help your installer with getting perfect fabric alignment during installation.

- No fastening screws, adhesives, tapes, glues, wedges, shims or luck required to get a perfect lifetime fit to the roller tube. It just works.